Description

Advantages

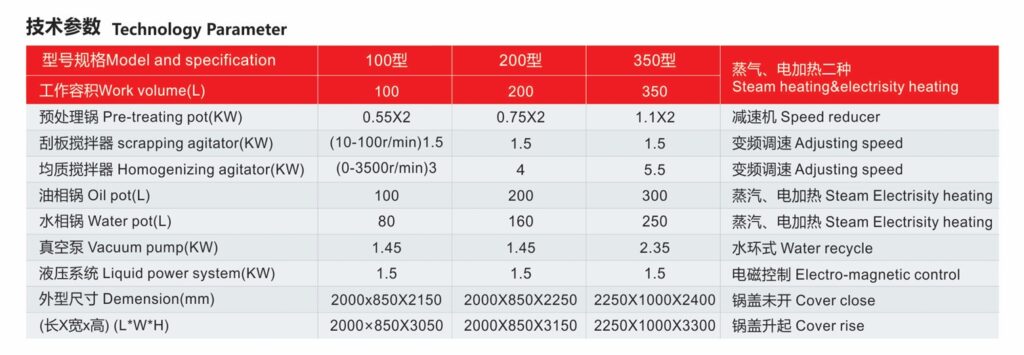

This machine adopts upper coaxial tertiary mixer, hydraulic pressure lift cover opening, rotate speed of rapid homogenate stirring: 0-3500r/Min (Frequency control), rotate speed of slow scrapping mixer. 10-1OOr/Min (Frequency control), the homogenate head adopts high shear turbulent emulsification mixer, slow scrapping stirring automatic cling to the bottom of the pot and the wall. It adopts vacuum suction, vacuum suction to powder material avoids dust flying specially. The entire working procedure carries on under vacuum condition, prevents the material producing bubble after high speed stirring to reach sanitary and aseptic.

This system equips with CIP cleaning system, the contact department of vessel and material are SUS316L material. the internal surface mirror surface polish 300EMSH(hygienic level)in order to guarantee the control section to be stable.

specially designed according to the cream-making technology of cosmetics and medicinal ointment. This machine is composed of pretreated pot, vacuum emulsification stirrer, vacuum pump, hydraulic system, discharge system, and electric appliance control system and work plane.

Usage

This machine is applied to produce cream and frost products for cosmetics and medicine factories. the emulsification function is specially obvious especially to the material with high adhesive and high content of solid material.

Reviews

There are no reviews yet.