Description

Advantages

This machine adopts upper coaxial dual agitator, liquid power to lift and down to open cover, fast homogenizing agitator rotary speed: 0-1400r/min (frequency control), slow scrapping agitator rotary speed: 10-IOOr/min (infinite speed variation), the homogenizing head adopts high cut eddy emulsifying agitating machine, slow scrapping agitator automatic tightly oppressed to the pot bottom and pot inner surface. In the agitating process, rotary pump outer recycle the material to completely emulsify the material. Vacuum absorbing material, especially absorbing powder is adopted to avoid powder and tiny dust fly. The whole process undergoes in vacuum condition to avoid material to produce bubbles in the high speed agitating, up to sanitary standard.

The material allotted is auto transferred by liquid Jevel auto control to packaging container. This system is fixed with CIP cleaning system, and the part in touch with the mate rial adopts SUS316L stainless steel, inner surface mirror polish 300EMSH (sanitary class). This machine completely accords with GMP standard, and is the most advanced and ideal suppository allotting equipment.

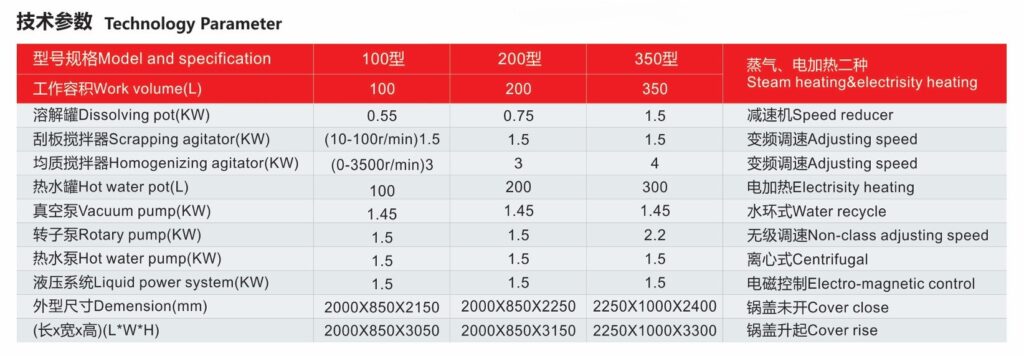

This machine consists of host dissolving pot, vacuum emulsifying agitating pot, hot water pot, rotary pump, vacuum pump, hot water sanitary pump, liquid pressure system, electric controlling system, and work platform.

Usage

This machine applies to allot suppository medicine, has a great effect in allotting the material of oil, frost, water dissolving, and especially high host density, and material containing high solid matter.

Reviews

There are no reviews yet.