Description

The basic conditions for fermentation tank

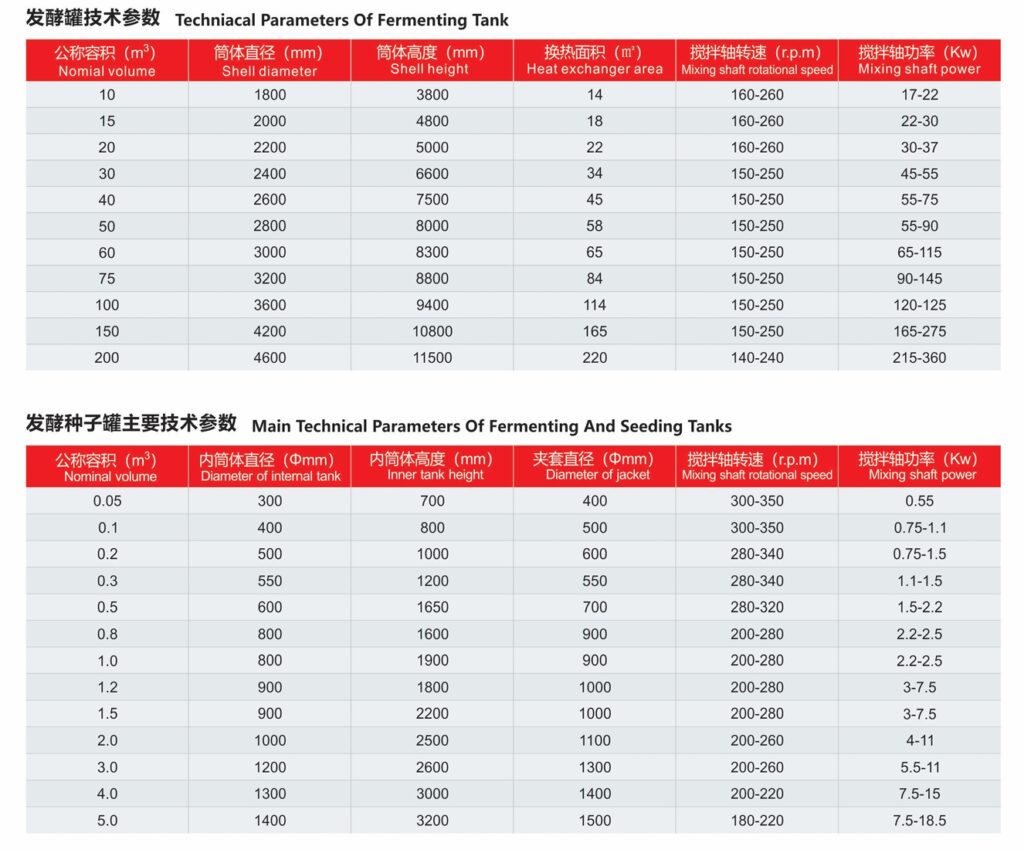

Mechanical agitation fermentation tank is one of the types commonly used in fermentation plant. It uses mechanical mixers to well mix air and the organization, so that prompt the oxygen dissolved in organization in order to ensure the supply of oxygen in microbial growth and reproduction. Fermentation. Making fermentation tank would have to meet several basic requirements as follows:

1.Fermentation tank should have suitable ratio of height and diameter. The ratio is generally about 1.7 to 4 times. the longer the tank body. The higher the utilization of oxygen.

2 .Fermentation tank can withstand certain pressure. When fermentation tank in the disinfection and normal working hours. there is certain pressure (hydraulic and pneumatic)and temperature in the tank, so the tank components must have certain strength and withstand some pressure

3.The ventilation device in fermentation tank make the gas-liquid mixture ully mixed to ensure that the broth must dissolve oxygen.

4.Femlentation tank should have sufficient cooling area. In microbial growth and metabolism process it emits a lot of In order to control the temperature in fermentation process at different stages. it should be equipped with adequate cooling area.

5.Fermentation tank must minimize the corner to avoid scale plot of sewage, so it Can be thoroughly sterilized to avoid Ranjun.

6.The seal of agitator should be tight to minimize

Fermentation tank body size ratio

The size of every part of the tank must has a certain ratio The ratio of height and diameter of the tank is about 1.7 to 4 times.

Fermentation usually equipped with two blenders. the distance between the two groups blender S is about three times as the diameter of the blender. For large-scale fermentation tank and which has deep liquid depth HL. Install three sets of three or more of the blender. The blender at the bottom is usually closer to the wind for good. and the distance to the bottom of the tank C is equivalent to the diameter of the blender Di. but not less than 0.8 Di. otherwise it will affect the cycle of liquid.

The structure of fermentation tank

Aerobic fermentation tank mechanical agitation is a sealed compression equipment, including the main components. Mixers, seal, a bubble. Couplings. intermediate bearings, blowing bubbles of air(or air-jet), baffle. Cooling device, manhole and pipeline.

Reviews

There are no reviews yet.